Change of filler material

This is a guide on how to read a filler materials classification and rules when it is possible to change the filler material.

Terms for changing the filler material as flux cored electrode or covered electrode

- In order to change a filler material, everything within the red marking must be identical to what is stated in the classification for the filler material. This is called the mandatory part of the classification. If this classification does not match, new welding procedures must be produced on all geometries.

- The part behind the second red line, i.e., the hydrogen number must be the same or lower to be able to change the filler material. If the hydrogen number is higher, new welding procedures must be produced on all geometries.

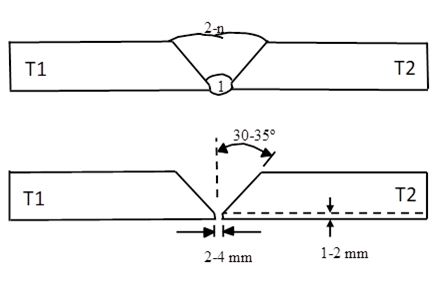

- If the weld is a butt weld and the classification is identical to the above, a new butt weld procedure must be welded. In this procedure, only impact strength testing is done to obtain the correct impact strength values.

Example of classification for tubular cored electrode/ T422ZPM211H5 according to ISO 17632-A

Legend:

T = Tube

42 = Strength and elongation (42 = 420 MPa or N/mm² in tensile strength)

2 = Symbol for impact properties (2 = Temperature -20°C and at least 47 Joule impact energy)

Z = Symbol for chemical composition for all-weld metal (Z = unknown chemical components)

P = Symbol for type of electrode core (P = Rutile slow freezing slag, (M = Metal powder))

M21 = Symbol for shielding gas (M = Mixed gas according to ISO 14175)

1 = Symbol for welding position (1 = all positions)

H5 = Symbol indication the hydrogen content of deposited metal (H5 = ≤5 ml hydrogen/100g deposited metal)

The red highlighted part of the code above represents the part of the classification that is mandatory.

Example of classification of covered electrodes E424B42H5 according to ISO 2560-A

Legend:

E = Covered Electrode

42 = Strength and elongation (42 = 420 MPa or N/mm² in tensile strength)

4 = Symbol for impact properties for all-weld metal (4 =Temperature -40°C and at least 47 Joule impact energy)

B = Symbol for the type of electrode covering (B = Basic covering)

4 = Symbol for nominal electrode efficiency and type of current (4 = 105-125 % and DC)

2 = Symbol for welding position (2 = All positions except for welding vertical down)

H5 = Symbol indication the hydrogen content of deposited metal (H5 = ≤5 ml hydrogen/100g deposited metal)

The red highlighted part of the code above represents the part of the classification that is mandatory.

Example of classification for wire electrodes G422M21G4Si1 according to ISO 14341

Legend:

G = Wire electrode

42 = Strength and elongation (42 = 420 MPa or N/mm² in tensile strength)

2 = Symbol for impact properties (2 = Temperature -20°C and at least 47 Joule impact energy)

M21 = Symbol for shielding gas (M = Mixed gas according to ISO 14175)

G4Si1 = Symbol for the chemical composition of wire electrodes

Terms for changing wire electrode:

To be able to replace a wire electrode, the entire classification must match. However, no new samples are required to be welded up if the classification is identical. This applies to both fillet and butt welds.

The red highlighted part of the code above represents the part of the classification that is mandatory.